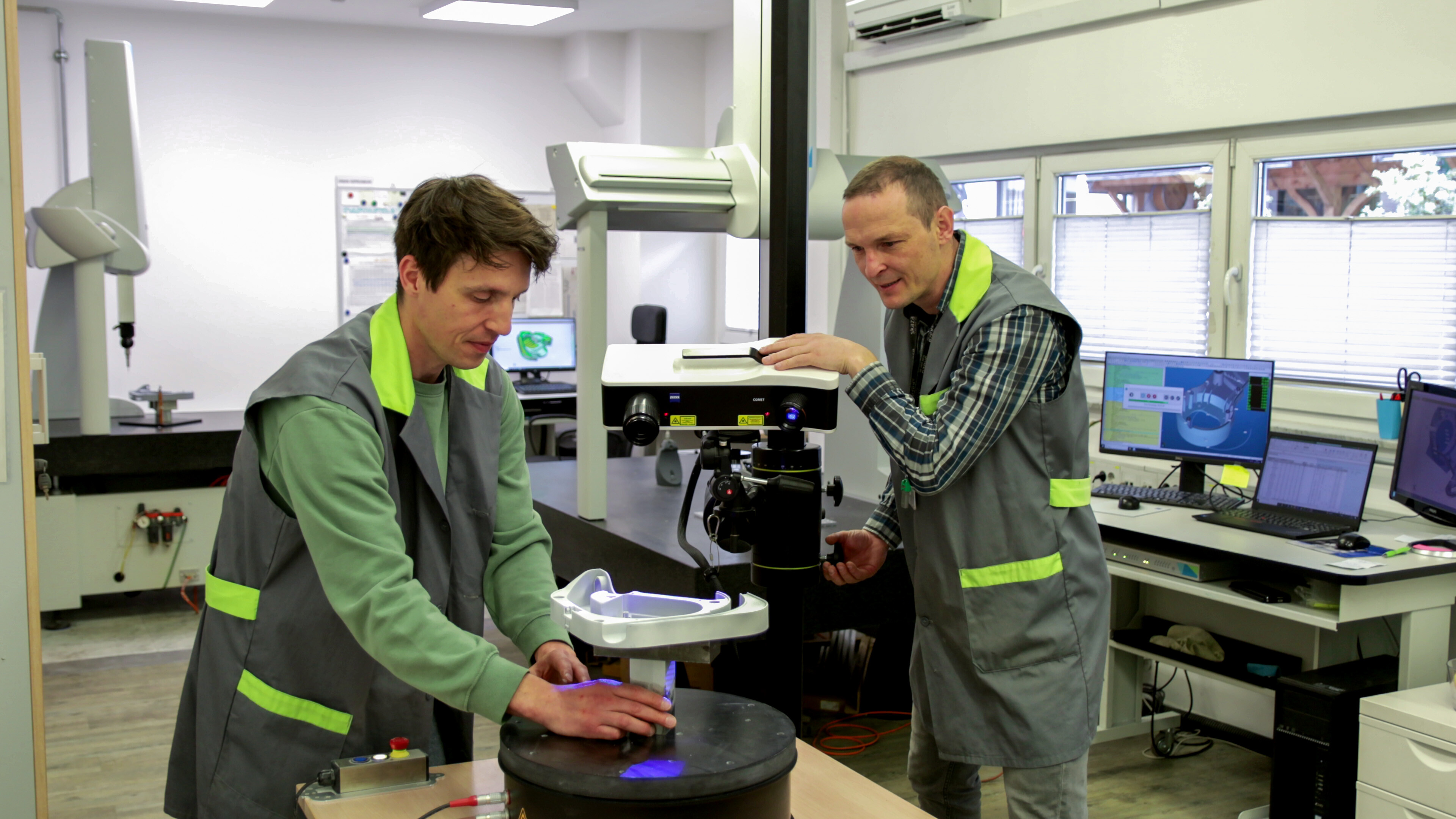

METERING SERVICES

We offer state-of-the-art metering services tailored to your needs.

We offer the most advanced technology like CMM, 3D scanning, 2D profile projection, and spectrophotometry.

We excel at combining and analysing data from different measurement technologies for better reliability.

We tailor control protocols and analysis methods to provide accurate and relevant data tailored to your needs.

By maintaining good metrology practices and quality standards, we guarantee the reliability of our measurements.

Innovation and sustainability in every phase of collaborating with us

![Development supplier | Concept & Design Development]()

1 - Concept & Design Development

We offer guidance and optimization on sustainable product design, component functionality, and selecting recycled or bio-based materials. Our focus on sustainability ensures that products are both functional and environmentally responsible.![Development supplier | Engineering]()

2 - Engineering

Our commitment is to plan and execute optimized and cost-efficient plastic injection molding processes. We conduct feasibility studies and ensure the most effective TCO outcomes for our partners.![Development supplier | Tooling]()

3 - Tooling

We collaborate with trusted, long-term partners to ensure a rapid and efficient tooling process while maintaining the right storage and maintenance of the tools.![Development Supplier | Mass Production & Manufacturing]()

4 - Mass Production & Manufacturing

With a machine park featuring over 55 injection molding machines, ranging from 50 to 1,000 tons of clamping force, we can handle all product sizes. Our 15,400 m2 manufacturing area is primed for large-scale production, capable of delivering millions of units annually.![Development supplier | Tooling]()

5 - Continuous Improvements

We embrace digitalization to optimize processes, streamline workspaces, and reduce material waste. This ensures ongoing efficiency even after the project transitions to the production phase.![Development Supplier | Highest Quality-Controlled Process]()

6 - Highest Quality-Controlled Process

Our strict process control methodologies are designed to reduce material waste and minimize energy consumption, enhancing sustainability and reducing costs.![Development Supplier | Logistics]()

7- Logistics

Our approach focuses on an efficient process by minimizing transportation routes, reducing wait times, introducing green technologies, and utilizing sustainable packaging methods in the production process.![Development Supplier | Sales & Marketing]()

8 - Sales & Marketing

Our in-house capabilities in sales and marketing manage the bulk distribution, wholesale, and private label of our own-brand products, specifically designed from recycled plastics and made for responsible organic waste handling.

NEED METERING SERVICES?

Measurement technologies

CMM (Coordinate Measuring Machine)

- Measurements using CMM (Coordinate Measuring Machine) are crucial in modern manufacturing for ensuring product quality and precision, as they enable detailed and accurate measurements that meet strict standards. It is a measurement method that uses a probe to determine coordinate points on the surface of the product. This allows us to measure the dimensions, geometry, and shape of complex parts.

3D scanning

- Optical 3D scanning is a non-contact measurement technology that results in a three-dimensional structure of an object. It is widely used in various industries for quality analysis, compliance verification with designs, creating digital copies of existing objects, and reverse engineering. It is most suitable for measuring irregular shapes, flatness, or when measuring soft materials.

2D profile projection

- A 2D profile projector is a valuable tool in quality control and metrology, designed for measuring the dimensions and profiles of 2D parts through visual inspection with moderate accuracy. It is still widely used in industries where measurement of simple 2D geometries is sufficient for ensuring product quality and compliance with specifications. It is most commonly used for checking the dimensions of flat and projected surfaces. It is suitable for measuring key dimensions of serial parts.

Color spectrophotometry

- Color spectrophotometry is a technique used to measure and quantify the color of substances based on their spectral properties. This technique analyzes how materials absorb, reflect, or transmit light at different wavelengths within the visible spectrum.

Why should you contact us?

Our employees are experts in measuring technology and plastic injection moulding. We have the latest measuring equipment from leading manufacturers and we work individually on each project, proposing solutions to meet your specific needs. We provide reliable and accurate measurements to help you make the right decisions.

Our metering services are suitable for:

- Dimensional Control: We verify the dimensions of your products according to technical specifications. We specialize in the inspection of plastic products, but we also handle other materials with ease.

- Reverse Engineering: Using measurement technologies, knowledge, and experience, we provide support for reverse engineering.

- Design Support: We provide the measurement data necessary for optimizing the design of your products.

.png?width=300&name=Developing%20new%20recycled%20materials%20(1).png)