Innovation & projects

SEARCHING FOR A RELIABLE PARTNER IN EUROPE?

Innovative projects that are helping us change the industry

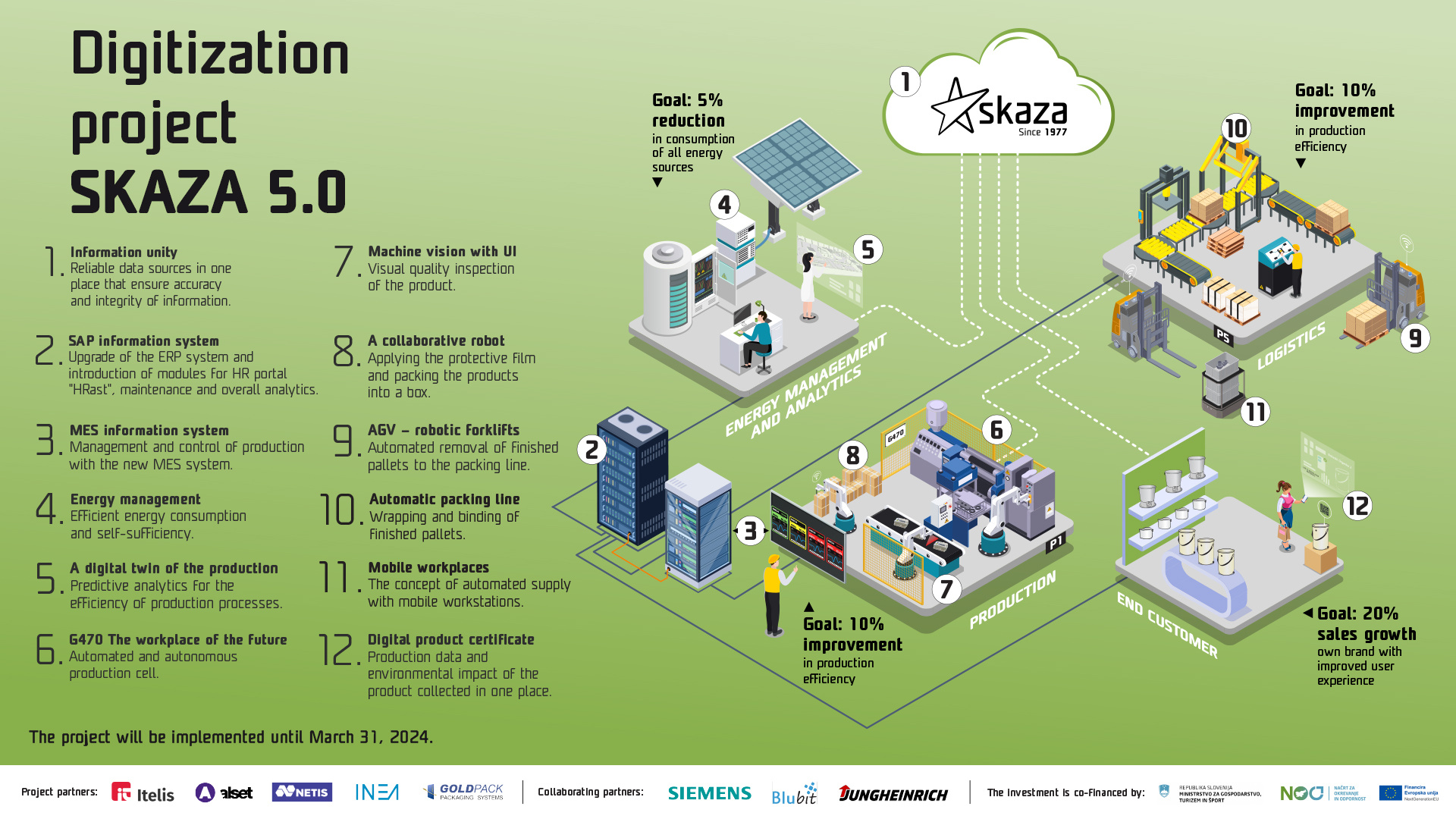

DIGITALIZATION 5.0

We actively participate in the Digitalization 5.0 project initiated by us. As a key contributor, we join forces with other companies and leverage our expertise to drive innovation and sustainability in the plastic industry. Our collaboration focuses on implementing new technologies, including a digital product passport, machine vision with artificial intelligence, and various forms of production automation. The project, valued at over 4.2 million euros, is a significant step toward Industry 5.0, emphasizing empowering employees rather than achieving complete automation. Our involvement underscores our dedication to driving positive change in the industry, contributing to a more sustainable future.

LFIA-REC

In our pivotal role within the project, we are committed to transforming waste management post-Covid-19. Collaborating with leading partners, including the Faculty of Mechanical Engineering, University of Maribor, our focus is to recycle discarded nanogold-based tests efficiently. By disassembling and separating components like gold and plastic, we aim to reduce the environmental impact caused by incineration, curb greenhouse gas emissions, and promote circular economy principles. Aligned with the EU's Circular Economy Action Plan, this initiative, funded by the Norwegian Financial Mechanism intends to develop an innovative process for recycling rapid tests into high-value secondary raw materials, fostering sustainability and best practices in recycling. See news on this topic »

LIFE21-ENV-PL-PLASTICLIFECYCLE

Partnering with INVESTEKO SA, THE NEW RAW, EkoPartner, EFOE, and IETU, we are spearheading the recycling of mixed waste from hard plastics. Aligned with the European strategy for plastics, our efforts aim to increase the share of recycled plastic in new products by 2025. Funding for this initiative is secured through the LIFE Program of the European Union for Environment and Climate Actions. We focus on establishing a modular prototype system for compounding recyclates, contributing to systematically introducing recycled materials into products. This project, titled "The solution for the management of mixed hard PLASTIC waste by applying CIrCuLar Economy approach; LIFE21-ENV-PL-plasticLIFEcycle," has an estimated value of EUR 3,830,295.05 and co-financing amounting to EUR 2,298,174.00. See news on this topic »

INCREACE

We take a pioneering role as the sole Slovenian partner in the INCREACE European research project, funded by Horizon Europe. Leading a critical research study within the project, we focus on developing advanced recyclates for electric smart meters and electric vehicle charging stations. The project addresses the challenge of stringent safety requirements limiting the use of recycled materials in electrical equipment. Successful development of recyclates is poised to be a breakthrough, contributing to broader goals of reducing greenhouse gas emissions and preventing plastic waste pollution. This initiative positions us as a leader in sustainable solutions and aligns with the European Plastics Strategy's objective of increasing recycled plastic usage in high-value products. See news on this topic »

Innovation in every phase of collaborating with us

![Development supplier | Concept & Design Development]()

1 - Concept & Design Development

We offer guidance and optimization on sustainable product design, component functionality, and selecting recycled or bio-based materials. Our focus on sustainability ensures that products are both functional and environmentally responsible.![Development supplier | Engineering]()

2 - Engineering

Our commitment is to plan and execute optimized and cost-efficient plastic injection molding processes. We conduct feasibility studies and ensure the most effective TCO outcomes for our partners.![Development supplier | Tooling]()

3 - Tooling

We collaborate with trusted, long-term partners to ensure a rapid and efficient tooling process while maintaining the right storage and maintenance of the tools.![Development Supplier | Mass Production & Manufacturing]()

4 - Mass Production & Manufacturing

With a machine park featuring over 55 injection molding machines, ranging from 50 to 1,000 tons of clamping force, we can handle all product sizes. Our 15,400 m2 manufacturing area is primed for large-scale production, capable of delivering millions of units annually.![Development supplier | Tooling]()

5 - Continuous Improvements

We embrace digitalization to optimize processes, streamline workspaces, and reduce material waste. This ensures ongoing efficiency even after the project transitions to the production phase.![Development Supplier | Highest Quality-Controlled Process]()

6 - Highest Quality-Controlled Process

Our strict process control methodologies are designed to reduce material waste and minimize energy consumption, enhancing sustainability and reducing costs.![Development Supplier | Logistics]()

7- Logistics

Our approach focuses on an efficient process by minimizing transportation routes, reducing wait times, introducing green technologies, and utilizing sustainable packaging methods in the production process.![Development Supplier | Sales & Marketing]()

8 - Sales & Marketing

Our in-house capabilities in sales and marketing manage the bulk distribution, wholesale, and private label of our own-brand products, specifically designed from recycled plastics and made for responsible organic waste handling.

.png?width=300&name=Developing%20new%20recycled%20materials%20(1).png)