Plastic Revolution for E-mobility

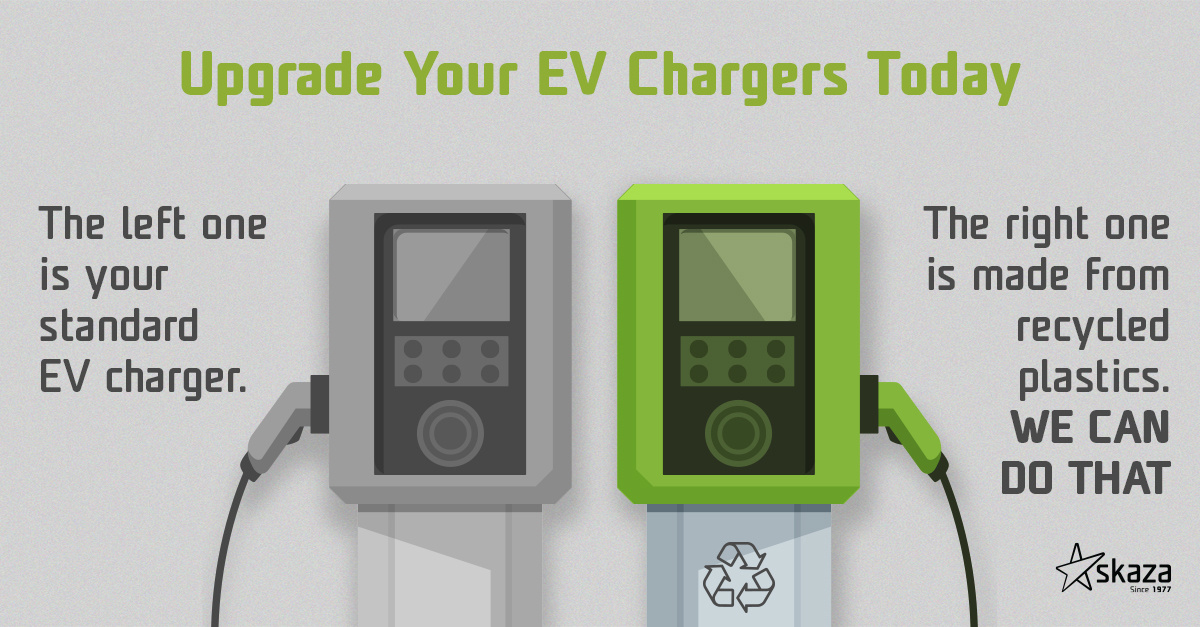

Join us on our rEVolution in using recycled materials for EV charger housings. Using recycled plastics can be your marketing advantage, appealing to eco-conscious consumers and differentiating from competitors.

SEARCHING FOR A RELIABLE PARTNER IN EUROPE?

Be brave enough to transform the industry

EV chargers from recycled plastics

Using recycled plastics can be your marketing advantage, appealing to eco-conscious consumers and differentiating from competitors. Additionally, it demonstrates your corporate social responsibility and may qualify your business for government incentives. Adopting recycled plastics also enhances supply chain resilience by diversifying sourcing options.

Cost-optimization & competitive price

Compared to metal housings, choosing plastics for your next EV charger provides cost-effective solutions without compromising quality. The versatility of plastics allows for efficient manufacturing processes, reducing production expenses. This extends throughout the product life cycle since plastics balance strength and longevity remarkably.

Switch to lightweight durability

One of the advantages of plastic housing is its lightweight nature, which reduces shipping costs and simplifies the installation process. This enhances the user experience, providing convenience in both shipping and installation. Plastic housing also ensures a more agile and user-friendly approach, aligning with modern expectations for efficient, adaptable, and economical solutions.

Lower environmental impact

Using recycled plastics extends beyond economic considerations - it's a commitment to environmental responsibility. Choosing recycled plastics minimizes the demand for virgin plastic production and participates in the global effort towards a healthier planet. Opting for recycled plastics isn't just your business decision; it's a responsible approach that resonates positively with your consumers.

We Cover It All.

Innovation and sustainability in every phase of collaborating with us

![Development supplier | Concept & Design Development]()

1 - Concept & Design Development

We offer guidance and optimization on sustainable product design, component functionality, and selecting recycled or bio-based materials. Our focus on sustainability ensures that products are both functional and environmentally responsible.![Development supplier | Engineering]()

2 - Engineering

Our commitment is to plan and execute optimized and cost-efficient plastic injection molding processes. We conduct feasibility studies and ensure the most effective TCO outcomes for our partners.![Development supplier | Tooling]()

3 - Tooling

We collaborate with trusted, long-term partners to ensure a rapid and efficient tooling process while maintaining the right storage and maintenance of the tools.![Development Supplier | Mass Production & Manufacturing]()

4 - Mass Production & Manufacturing

With a machine park featuring over 55 injection molding machines, ranging from 50 to 1,000 tons of clamping force, we can handle all product sizes. Our 15,400 m2 manufacturing area is primed for large-scale production, capable of delivering millions of units annually.![Development supplier | Tooling]()

5 - Continuous Improvements

We embrace digitalization to optimize processes, streamline workspaces, and reduce material waste. This ensures ongoing efficiency even after the project transitions to the production phase.![Development Supplier | Highest Quality-Controlled Process]()

6 - Highest Quality-Controlled Process

Our strict process control methodologies are designed to reduce material waste and minimize energy consumption, enhancing sustainability and reducing costs.![Development Supplier | Logistics]()

7- Logistics

Our approach focuses on an efficient process by minimizing transportation routes, reducing wait times, introducing green technologies, and utilizing sustainable packaging methods in the production process.![Development Supplier | Sales & Marketing]()

8 - Sales & Marketing

Our in-house capabilities in sales and marketing manage the bulk distribution, wholesale, and private label of our own-brand products, specifically designed from recycled plastics and made for responsible organic waste handling.

LET'S START YOUR NEXT PROJECT TOGETHER

PRODUCT PORTFOLIO

Innovation meets sustainability in our EV charger product portfolio. What sets us apart is not just our commitment to manufacturing high-quality chargers but our distinctive approach to sustainability. We revolutionize the industry by utilizing recycled plastics delivering eco-friendly charging solutions without compromising performance.

E-mobilityEV charger

Material: PC

Technology: 1K injection molding, assembly

Additional specs: IK 10, IP56

E-mobilityINCH core

Material: PC in PCGF10 in TPE

Technology: 1K & 2K injection molding, ultrasonic welding.

Fill in the form below and talk to our experts.

.png?width=300&name=Developing%20new%20recycled%20materials%20(1).png)