Our Services

Solutions, tailored to your needs

In cooperation with us, you can ensure high-quality and long-lasting solutions and lower total costs of product development (total cost of ownership), as we carry out the entire product development for you, optimize production costs, and propose alternative sustainable materials.

.jpg?width=300&name=Development%20Supplier%20(1).jpg)

From precision assembly to packaging, our solutions are designed to enhance the final presentation and functionality of your products. Trust us to deliver a comprehensive solution that encapsulates precision, reliability, and aesthetic appeal in every package.

Learn more about this service

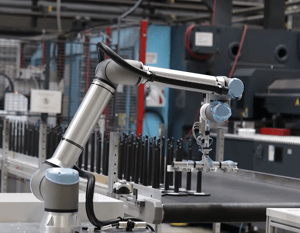

In your project, experience robots that operate autonomously and deliver efficiency. Embrace cost-effectiveness as we transform materials and design for maximum impact. Let us elevate productivity through automation while continuously optimizing processes for peak performance.

Interested in more?

Benefit from our 45+ years of expertise, where we lead as pioneers in plastic manufacturing. The outcome of collaborating with us will be precision, innovation, sustainability, assured quality, and efficient production processes, forging us as your trusted collaborator in delivering exceptional plastic products.

More about our expertiseSkaza represents stability to partners, as we are a reliable company, successfully operating since 1977.

LET'S START YOUR NEXT PROJECT TOGETHER

Partner with a company committed to sustainability ♻️

Collaborating with a company that embodies sustainability in its very DNA is a transformative experience. Our commitment to environmental responsibility goes far beyond buzzwords and green initiatives. Sustainability is an integral part of our identity, driving every aspect of our business.

- Innovative eco-friendly solutions: Our expertise in sustainable materials, processes, and design ensures that your projects are environmentally responsible and cost-effective.

- Reduced environmental footprint: We minimize our environmental impact. This helps the planet and improves the overall efficiency of your projects.

- A shared vision: Together, we can create products and solutions that contribute to a greener world.