45+ years of expertise

We are your stable, trustworthy partner, operating since 1977.

SEARCHING FOR A RELIABLE PARTNER IN EUROPE?

Innovation and sustainability in every phase of collaborating with us

![Development supplier | Concept & Design Development]()

1 - Concept & Design Development

We offer guidance and optimization on sustainable product design, component functionality, and selecting recycled or bio-based materials. Our focus on sustainability ensures that products are both functional and environmentally responsible.![Development supplier | Engineering]()

2 - Engineering

Our commitment is to plan and execute optimized and cost-efficient plastic injection molding processes. We conduct feasibility studies and ensure the most effective TCO outcomes for our partners.![Development supplier | Tooling]()

3 - Tooling

We collaborate with trusted, long-term partners to ensure a rapid and efficient tooling process while maintaining the right storage and maintenance of the tools.![Development Supplier | Mass Production & Manufacturing]()

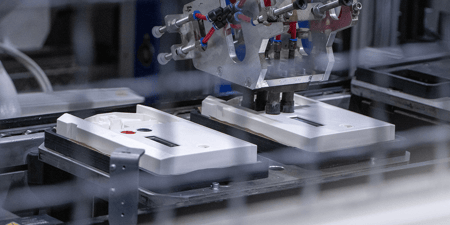

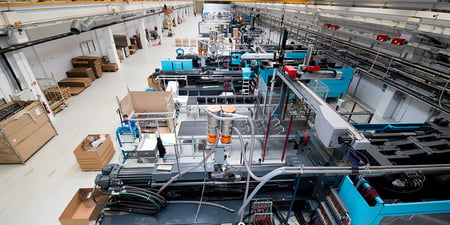

4 - Mass Production & Manufacturing

With a machine park featuring over 55 injection molding machines, ranging from 50 to 1,000 tons of clamping force, we can handle all product sizes. Our 15,400 m2 manufacturing area is primed for large-scale production, capable of delivering millions of units annually.![Development supplier | Tooling]()

5 - Continuous Improvements

We embrace digitalization to optimize processes, streamline workspaces, and reduce material waste. This ensures ongoing efficiency even after the project transitions to the production phase.![Development Supplier | Highest Quality-Controlled Process]()

6 - Highest Quality-Controlled Process

Our strict process control methodologies are designed to reduce material waste and minimize energy consumption, enhancing sustainability and reducing costs.![Development Supplier | Logistics]()

7- Logistics

Our approach focuses on an efficient process by minimizing transportation routes, reducing wait times, introducing green technologies, and utilizing sustainable packaging methods in the production process.![Development Supplier | Sales & Marketing]()

8 - Sales & Marketing

Our in-house capabilities in sales and marketing manage the bulk distribution, wholesale, and private label of our own-brand products, specifically designed from recycled plastics and made for responsible organic waste handling.

Decades of development and significant milestones

The story of Skaza started in 1977 - in the garage. The areas in which the first production began have increased by as much as 44 times in just a few years. We started on 350 m2 and currently operating on more than 15,400 m2. Today, we employ 50 times more employees and work with the most modern machines and technologies.

1977

Plastika Skaza was established

Our family company was established in a garage by Franc and Martina Skaza.

1985

Growth and development from a garage to a manufacturing company

Manufacturing surface: 150 m2 + 200 m2

Machine park: 5 machines

Number of employees: 6

1991

Renovated production facilities

Manufacturing surface: 150 m2 + 200 m2

Machine park: 10 machines

Number of employees: 12

.jpg?width=450&height=225&name=Karierni%20in%20osebni%20razvoj%20zaposlenih%20v%20Skazi%20(2).jpg)

2000

Upgrading with the area of 230 m2; Igor Skaza joins the company

Manufacturing surface: 1,520 m2

Machine park: 20 machines

Number of employees: 42

2004

Establishment of departments of Quality, Technology, Procurement, HR, Warehousing and Logistics; Tanja Skaza joins the company

Manufacturing surface: 2,000 m2

Machine park: 23 machines

Number of employees: 85

1997 - 2007, a decade of growth

Upgraded to an additional 1,100 m2, switched to 2K technology, and obtained certificate ISO 14001:2004

Manufacturing surface: 3,810 m2

Machine park: 38 machines

Number of employees: 93

2012

Launched brands Organko, Bokashi Organico, and Cuisine, and obtained certificate 9001:2008

Manufacturing surface: 3,810 m2

Machine park: 44 machines

Number of employees: 180

2017

Launched brands Skaza and Style Your Life, and obtained certificates ISO 9001, ISO 14001, BS OHSAS 18001:2007

Manufacturing surface: 15,400 m2

Machine park: 47 machines

Number of employees: 300+

2020

Obtained ISO 45001 certificate

Machine park: 51 machines

Number of employees: 280+

2022

Launched Organko Daily bin from post-consumer recycled plastics

Machine park: 51 machines

Number of employees: 280+

.png?width=450&height=225&name=Skaza%20uresni%C4%8Duje%20digitalno%20transformacijo%20z%20digitalnim%20dvoj%C4%8Dkom%20v%20proizvodnji%20%20(1).png)

2024+

Ready for the future

We will become partners' first choice when developing sustainable solutions and plastics products. We will keep co-creating sustainably oriented solutions for everyday use to raise people's awareness and contribute to a cleaner environment.

Decades of development and significant milestones

The story of Skaza started in 1977 - in the garage. The areas in which the first production began have increased by as much as 44 times in just a few years. We started on 350 m2 and currently operating on more than 15,400 m2. Today, we employ 50 times more employees and work with the most modern machines and technologies.

Today, we are ready for the future with daring vision, excellent knowledge, and high technology capabilities.

![Plastika Skaza - ready for the future]()

< 2025

Ready for the futureWe will become partners' first choice when developing sustainable solutions and plastics products. We will keep co-creating sustainably oriented solutions for everyday use to raise people's awareness and contribute to a cleaner environment.

![Achievements of Plastika Skaza in 2022: Organko Daily]()

< 2022

Machine park: 51 machines

Number of employees: 280+

Achievement: Organko Daily - made from post-consumer recycled plastics![Our vast and modernly equipped machine park features machines with clamping forces from 50T to 1000T]()

< 2020

Machine park: 50 machines

Number of employees: 280+

Obtained certificate: ISO 45001![Plastika Skaza own brand Bokashi Organico]()

< 2017

Manufacturing surface: 15,400 m2

Machine park: 47 machines

Number of employees: 300+

Achievements: own brands Bokashi Organico, Skaza, Style Your Life

Obtained certificates: ISO 9001, ISO 14001, BS OHSAS 18001:2007![Plastika Skaza own brand VIVA and Cuisine]()

< 2012

Manufacturing surface: 3,810 m2

Machine park: 44 machines

Number of employees: 180

Achievements: own brands Organko, Bokashi Organico, Cuisine

Obtained certificate: 9001:2008![2K and 3K technology of injection molding for smart meters]()

1997 - 2007

A decade of growthManufacturing surface: 3,810 m2

Machine park: 38 machines

Number of employees: 93

Achievements: upgrading to an area of 1,100 m2 (production and administrative part), use of 2K technology

Obtained certificate: ISO 14001:2004![Tanja Skaza joins the company in 2004]()

< 2004

Manufacturing surface: 2,000 m2

Machine park: 23 machines

Number of employees: 85

Achievements: the establishment of departments of quality, technology, procurement, HR, warehousing and logistics; Tanja Skaza joins the company![Igor Skaza joins the company in 2000]()

< 2000

Manufacturing surface: 1,520 m2

Machine park: 20 machines

Number of employees: 42

Achievements: upgrading with the area of 230 m2, Igor Skaza joins the company![Renovated production facilites of Plastika Skaza in 1991]()

< 1991

Manufacturing surface: 150 m2 + 200 m2

Machine park: 10 machines

Number of employees: 12

Achievements: renovated production facilities![Starting out in a garage]()

< 1985

Manufacturing surface: 150 m2 + 200 m2

Machine park: 5 machines

Number of employees: 6

Achievements: growth and development from a garage to a manufacturing company

LET'S START YOUR NEXT PROJECT TOGETHER

Our expertise is not measured in years, but in progress

Along with our 45+ years of tradition is a fascinating exploration of growth, innovation, and commitment. What started as a small enterprise has turned into a strong production force, capable of manufacturing millions of products each year. This journey is a journey of expansion, adaptation, and the continuous refinement of our products and services.

Explore the range and depth of our products and services. Explore the transformation from a small company to being one of the industry leaders.

.png?width=300&name=Developing%20new%20recycled%20materials%20(1).png)

.png?width=300&name=Skaza%20uresni%C4%8Duje%20digitalno%20transformacijo%20z%20digitalnim%20dvoj%C4%8Dkom%20v%20proizvodnji%20%20(1).png)

.jpg?width=300&name=Karierni%20in%20osebni%20razvoj%20zaposlenih%20v%20Skazi%20(2).jpg)