By their definition, polymers consist of a large number of repeating units. However, after adding certain supplements, they are no longer called polymers, but polymeric materials (plastic), which can be processed by various methods and are suitable for numerous products. In this blog, check out the classification of bioplastic to find out more.

Download our e-book about the sustainable materials we use in our manufacturing process >>

The first such plastics were produced in the late 19th and early 20th centuries. Since then, global plastic production has reached approximately 367 million tons yearly, with only a small portion of the plastic (2.1 million tons) representing bioplastics. Recently, however, the awareness about the finiteness of fossil resources, which are the primary source of plastics, is growing. Although it is still unclear at what point this would lead to an acute shortage, it is widely believed that this could happen within the next 50 years. Nevertheless, it will probably not happen because of the use of fossil resources for plastics and chemicals, but mainly because of their use for energy and transportation.

Only between 4 and 6% of fossil resources are used for plastics and chemicals, while 45% are used for transportation, and 42% are used for electricity and heating.

(Read more about sustainable materials on our blog.)

Most common classification of bioplastic

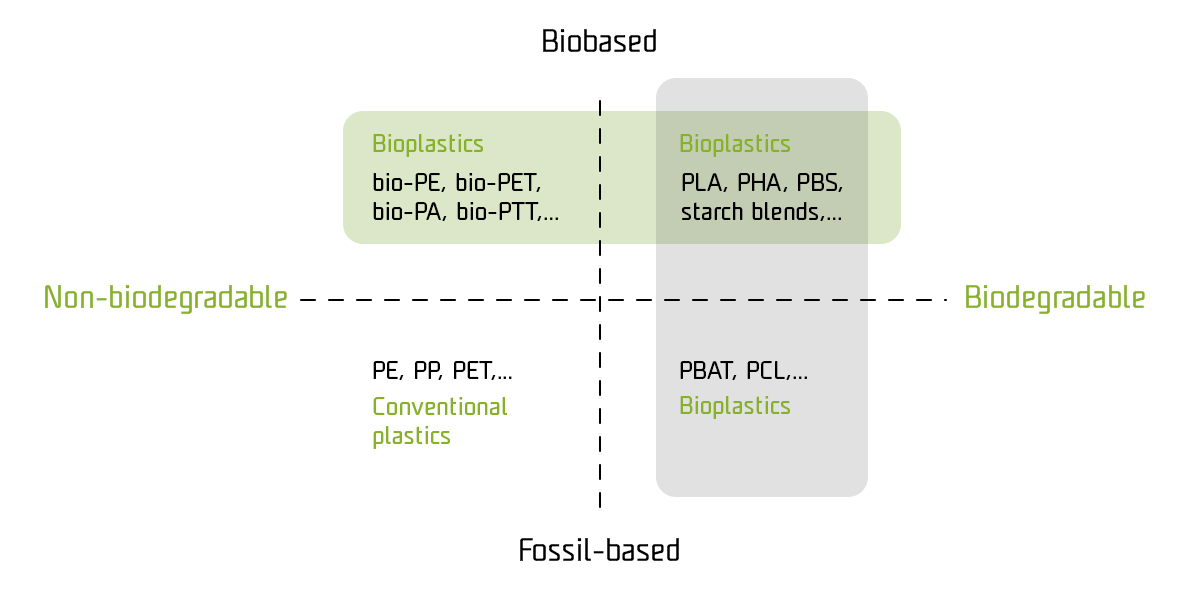

The most broadly used classification of bioplastic differentiates between bio-based materials and/or bio-degradable materials. Depending on the biodegradability and biobased content, plastics can be divided into four groups:

- Group 1: Bioplastics that are biobased or partially biobased and non-biodegradable, such as bio-PE, bio-PET, bio-PA, and bio-PTT.

- Group 2: Bioplastics that are biobased and biodegradable, such as PLA, PHA, PBS, and starch blends.

- Group 3: Bioplastics that are fossil-based and non-biodegradable, such as conventional PE, PP and PET.

- Group 4: Bioplastics that are fossil-based and biodegradable, such as PBAT and PCL.

Bioplastic classification between bio-based vs. fossil-based materials

According to this classification of bioplastic, conventional plastics produced from monomer building blocks derived from natural resources are called drop-in plastics. They have the same properties as their fossil-based analog and can therefore directly replace conventional fossil-based plastic. The prefix bio- in this case only means that this plastic is biobased. On the other hand, polycaprolactone is produced from monomer building blocks derived from fossil resources and is biodegradable, even compostable. However, they are both called bioplastics.

A large group of materials belonging to the bioplastics group introduces a lot of confusion regarding the origin of the material and their decomposition. Therefore, it would be useful to consider a clearer or more detailed classification of bioplastic in the future. The biodegradability and compostability of a material are completely independent of the origin of the material but depend solely on the chemical composition. The potential of bioplastic will definitely shape the future of the plastics industry.

Guest-blogging by: Assoc. Prof. Dr. Irena Pulko, PhD, Vice-Dean for Education

Find out more about how we incorporate sustainable materials into our production process. Fill in the form and download the e-book with educational content.