While industrial development has led to a more comfortable life for human civilization by providing us with unimaginable resources in an agrarian society, it has also brought us an enormous environmental burden in the form of depletion of non-renewable resources and pollution.

Download the case study about one of the strongest partnerships we build for more than 15 years >>

Only recently, we fully realized that the current path of industrialization would destroy our precious planet, which led to increased environmental awareness, reflected in focus on sustainable development and greener trends in plastic industry.

Circular economy is one of the most important trends in plastic industry

The plastic industry is also one of the main contributors to industrial pollution and resource consumption. However, the situation is getting brighter since a sharp shift from linear towards circular economy became one of the main trends in the plastic industry and is expected to grow stronger in the future.

The first step in this direction is developing greener plastic products by utilizing the principles of eco-design, a systematic approach to designing more environmentally friendly products. Here several different strategies are adopted, usually comprising of:

- the use of sustainable materials,

- reducing total use of materials,

- optimizing production techniques,

- decreasing product impact during use, and

- considering the product's end of life.

While eco-design is definitely one of the most promising trends in plastic industry, it cannot fulfill its role without efficient waste management. That is why in recent years, we see a shift in focus to employ the hierarchical waste management approach, which aims to treat waste according to the following order (from most to least favorable): prevention, reuse, recycling, recovery, and disposal.

More sustainable trends in plastic industry are also the core focus of Plastika Skaza's vision and mission. We always strive to decrease the negative environmental effect of plastic products on the environment, which is reflected in our product line. We aim to reduce the use of single-use plastic products by replacing them with multi-use plastic products designed and produced in a way that presents the least possible environmental burden. We achieve this by using renewable energy and sustainable materials that can be efficiently recycled.

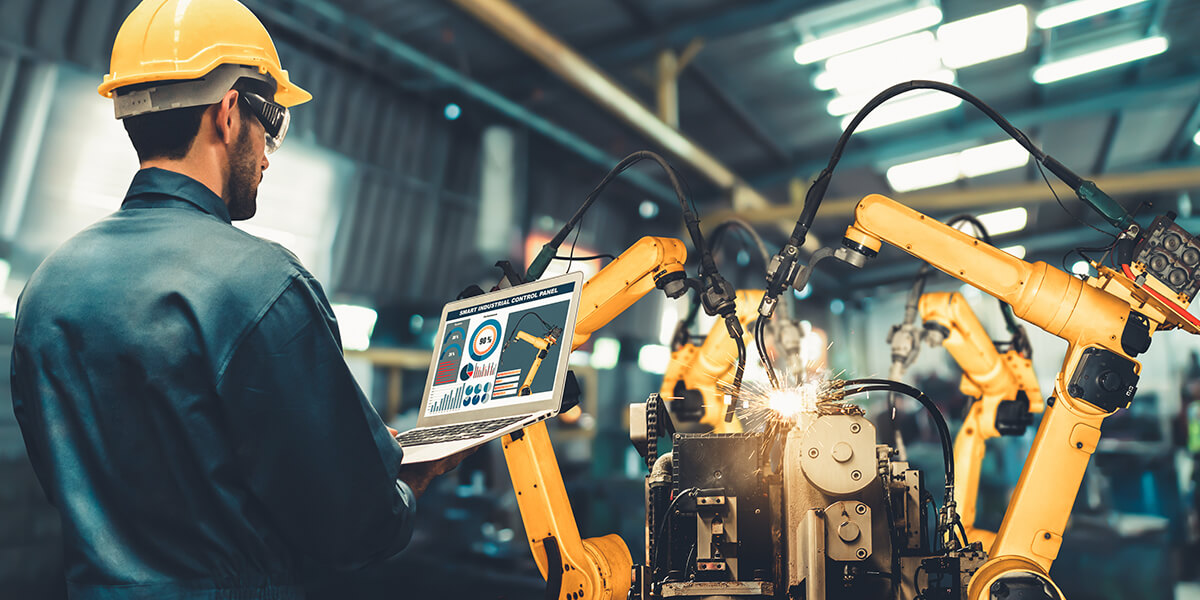

Industry 4.0 technologies

In the 18th century, the development of manufacturing machines that are powered using steam and water gave rise to the so-called first industrial revolution, which transformed the global economy by substituting manual labor with machine labor. The second industrial revolution happened in the 19th century by the installation of the extensive railroad and telegraph networks, which allowed the fast transfer of people, ideas and electricity. The development of computers in the late 20th century gave rise to a third industrial revolution, where extensive automation of manufacturing processes occurred. Currently, we are witnessing the implementation of a fourth industrial revolution or so-called Industry 4.0.

Industry 4.0 is the ongoing automation of manufacturing processes using modern smart technologies, such as machine-to-machine communication (M2M), the internet of things (IoT) and big data analytics. Like previous industrial revolutions, which completely transformed the global economy by introducing new technologies, Industry 4.0 promises to change how things are manufactured by introducing smart machines, which can operate autonomously and present new trends in plastic industry.

The biggest potentials for new trends in plastic industry lie in

- mass customization,

- efficient and flexible production,

- prediction of process and product quality.

Mass customization refers to a business strategy that offers highly customized products without the high costs by using flexible computer-aided manufacturing systems and novel production technologies, such as additive manufacturing (3D printing). Increased automation with flexible production technologies will result in more efficient processes, which don't require manual labor, thus decreasing production costs and offering humans to avoid repetitive tasks and focus their work on the things where they excel. Prediction of the processes and product quality will improve the quality of the products and prevent products with defects from entering the market, contributing to the increased reliability of the products.

Metal replacement

The early 20th century trends in plastic industry resulted in a huge success story where global plastic production increased from 2 million tons in 1950 to nearly 360 million tons in 2018 and is expected to triple by 2050. This global rise of plastics resulted from its unique properties, such as low production and processing costs, high design flexibility, low density, good corrosion resistance and unique mechanical properties.

Plastic materials gave rise to entirely new products, which were not possible to produce using traditional materials. On the other hand, they also started to substitute traditional materials (such as metals) in existing products. While replacing metals with plastic materials began shortly after the invention of synthetic polymers, it has still not realized its full potential. As typical plastic materials have significantly lower strength and stiffness than metals, the metal replacement first only began in less demanding applications. However, advancements in polymer and material science and engineering gave rise to new high-performance plastic materials, such as fibre reinforced plastics (FRP), which have physical properties that enable metal replacement in increasingly more demanding applications that were unimaginable a few years before.

Metal replacement is still one of the strongest trends in plastic industry, and polymers are still finding their way to a new application in different fields, such as mobility, aerospace, energy production, medical, furniture, sports equipment, etc.

Lightweight construction

Lightweight construction is another one of the more promising trends in plastic industry with a similar goal as a metal replacement. The lightweight construction aims to decrease the weight of the products by utilizing various methodologies, for example, by intelligent material combination, biomimicry (cellular and sandwich structures, fibre composites), functional integration (e.g. integration of sensors and actuators on a material level), etc. Decreased weight of the products offers many benefits, such as higher performance, increased resource efficiency and lower environmental impact.

An excellent partnership is a key to success. Fill in the form below and download our case study about milestones while building the future of energy with one of our biggest partners for more than 15 years.