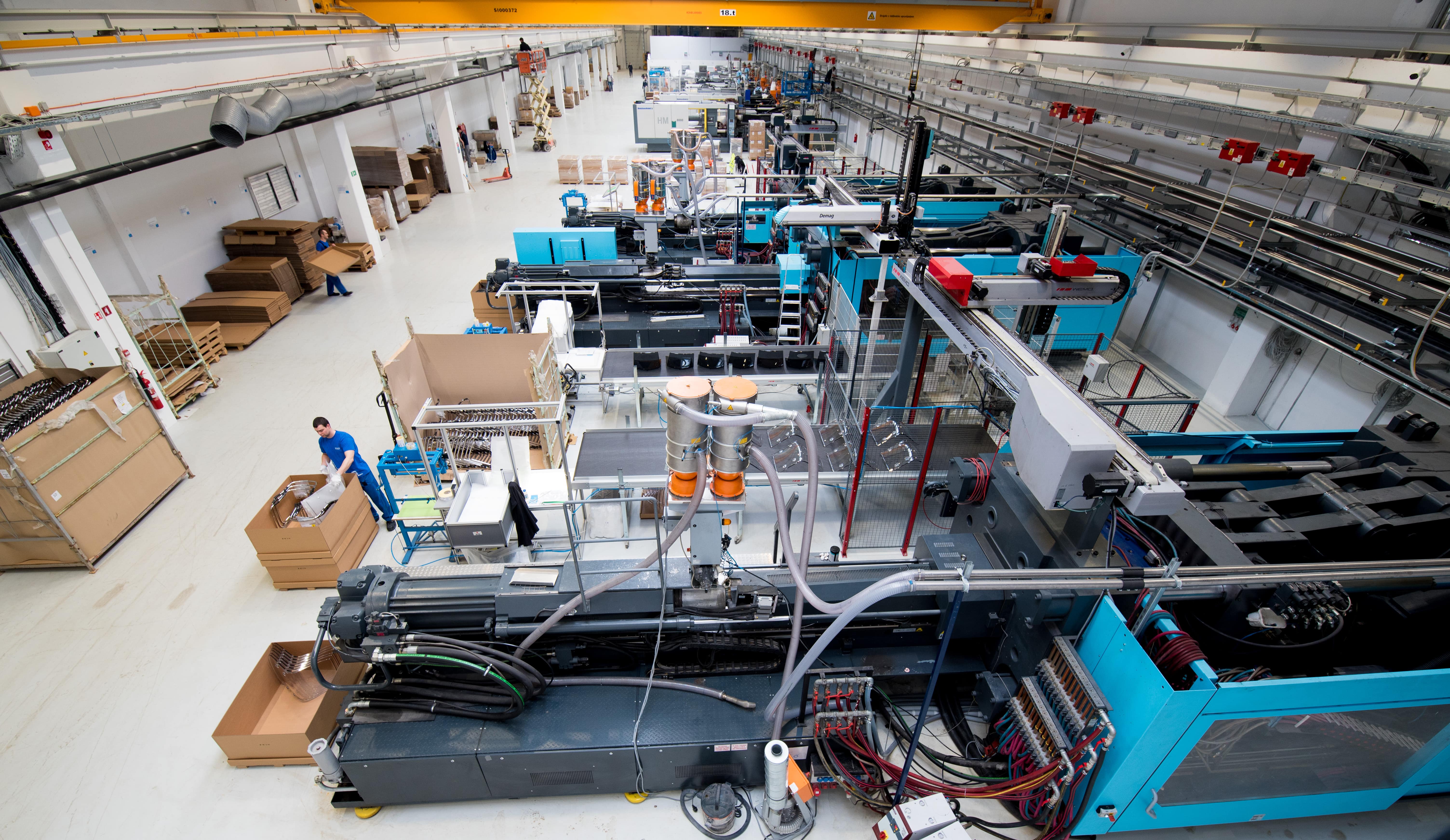

We are a manufacturer of plastics industrial products, a company that by injection molding creates new, technologically advanced and innovative solutions to approach and aim one of our goals – save the planet. We have shown our courage, commitment to ecology, agility, responsiveness, knowledge and experience by developing a new product. We proudly introduce you Bokashi Organko 2 Ocean, an innovative kitchen composter, made from recycled fishing nets.

Download our e-book about the sustainable materials we use in our manufacturing process >>

We spoke with Sebastjan Kotnik, Head of R&D and Operational Quality, who presented the skills, competencies and knowledge, necessary for the successful launch of a new product in every plastic industry.

1. How was the idea for such an environmentally friendly product born?

Sometimes, in plastic production, we hear that the world has to survive without plastic, abolish it, remove it from our homes, which is far from being easy and necessary. All we have to do is to "spin" used synthetic products correctly and give them a new life, a new environment and a new purpose. And that’s exactly what we did with Bokashi Organko 2 Ocean – we recycled fishing nets that originally served to fishermen and, after being used, endangered species and oceans, so now they can serve us in our households.

2. Could you briefly present the whole process from idea to implementation?

The idea arose one year ago on an internal Hackathon. We entered into a partnership with a technological processor of waste materials. It is a renewed synthetic material PA (polyamide), which previously was in the depths of the oceans for many years. A huge amount of testings followed, both in the lab and in the real environment. Based on the conclusions, here in plastic production, we improved the material recipes several times until we reached the desired result. The procedure was followed by experimental and 0 series, and now it is done. The first big series of Bokashi Organko 2 Ocean will see the light of day in October 2020.

3. Which materials were added during the process of recycling fishing nets? What is the process in general and how is it different from recycling “ordinary plastic”?

It all starts with collecting fishing nets in ports, at fishermen, as well as shipyards that carry out the renewal of the fishing fleet. The nets are then brought to a special plant, where they are ground into fine pieces, about 2 millimeters in size, followed by fractionation procedures. Simplified, we could say that fishing nets are "cooked" to a certain extent, de-polymerized, and then all impurities are removed (these are later used in the production of asphalt). Additives that refresh it are added to the cleaned material (UV resistance, thermal resistance, toughness additives), and then it is processed into granulate - into a form that can be processed with injection molding machines.

4. How fishing nets plastic differ from virgin plastic in terms of quality, composition and processing options?

The advantage of the certificate we have for this granulate is literally a guarantee that the synthetic plastic material was in the depths of the oceans many years before being used to make our Organko. It was a danger that was hundreds of meters deep and was constantly filling our plates, together with the seafood we eat. At the same time, the certificate ensures that all "technicality", i.e. mechanical, chemical and thermal properties, are fully returned to the material, and therefore it can easily compete with new, newly formed materials from crude oil.

5. Is the whole process of recycling fishing nets more expensive or cheaper than other processes?

In terms of cost of creation and the current corona situation we find ourselves in, where crude oil literally boils out of full storage at low prices, it is really hard to compete with other processes as far as affordability is concerned. But we are firmly determined that we should no longer produce only plastics industrial products from raw plastics. The time has come to properly recycle already used plastic, de-polymerize it and prepare it for new purposes.

6. How do we maintain the quality of the final product, given the fact that it is recycled from fishing nets?

In any case, the certificate alone does not guarantee that all the synthetic mass from the recycled material will always be perfect. Therefore, we have our own laboratory where we perform sampling and detailed testing of each shipment, such as material flow index, color properties, UV resistance and also mechanical properties. For this purpose, we also use the laboratory at our co-founded Faculty of Polymer Technology in Slovenj Gradec. There is no need to worry about material properties deviating too much because we take care of them every time.

7. What challenges do we face in the process and how do we solve them?

The challenges are healthy because they constantly remind us that we need to live our mission – not only to process synthetic masses but also to properly collect, process and obtain synthetic masses from end-of-life and brand-new products. FDA certification also plays a special role in the entire cycle. It is a food contact permit where we try our best and we are really close to reaching it, we will succeed!

8. How brave and daring is the project?

Anyone can pour new "virgin" synthetic material from the shelf or from the warehouse and by injection molding manufacture it without fear of changing its mechanical and aesthetic properties. But we are different. We want to challenge ourselves and live boldly. We are systematically delving into, for others, the delicate areas of recycling and regenerating waste materials. Of course, we do not do this blindly. We are prepared and well equipped with our knowledge and experiences. In this way, we are happy to find new areas of recycling and to take care of a cleaner environment. When will it be enough? When we become trendsetters in the field of recycling when we find recipes for all already used plastic products. So, we still have a lot of work and there is a lot of daring challenges ahead.

More about the Bokashi Organko 2 Ocean on our website..

Find out more about how we incorporate sustainable materials into our production process. Fill in the form and download the e-book with educational content.