The automated production line is the latest stage in the never-ending pursuit of faster, more effective, and less expensive ways of manufacturing items we need and want in our everyday lives.

Download the case study about one of the strongest partnerships we build for more than 15 years >>

It is in the nature of human beings to continually make improvements, especially when it comes to repetitive tasks. During the relatively short history of our existence, we have constantly demonstrated our ingenuity in optimizing every process within the society, most notably when it comes to production. We continue to do so, as there is always room for improvement.

Aims for the perfect automated production line

Our team at Skaza is following the same aspirations as we invest a lot of time and energy into finding new solutions and enhancements of our own automated production line of furniture components from sustainable materials.

Lowering costs and rising productivity have been the ultimate goal of every manufacturer ever since the first production lines were introduced during the industrial revolution in the late 18th century. This motto is still being followed today when advanced technology helps us bring the automated production line to its maximal potential.

Eliminating the human factor

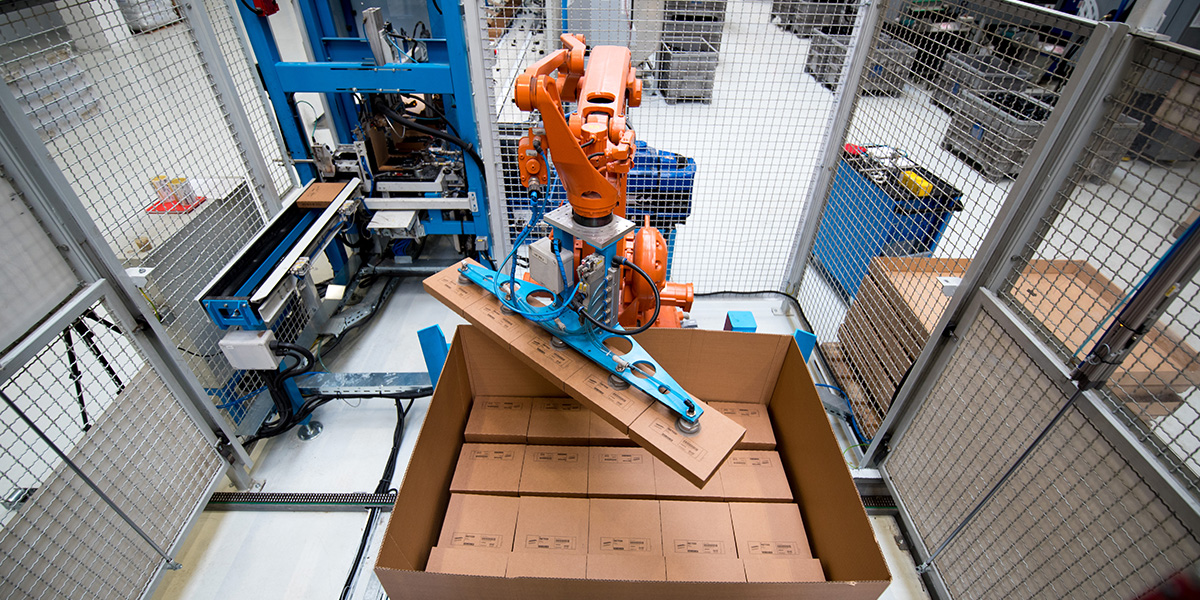

From a broader perspective of enhancing manufacturing processes within the society, automated production line represents an important step towards liberation from physical labor. People no longer need to perform hard, monotonous and usually lower-paid work since the ideal automated production line only requires a highly qualified supervisor. This not only improves cost efficiency but also introduces better job positions.

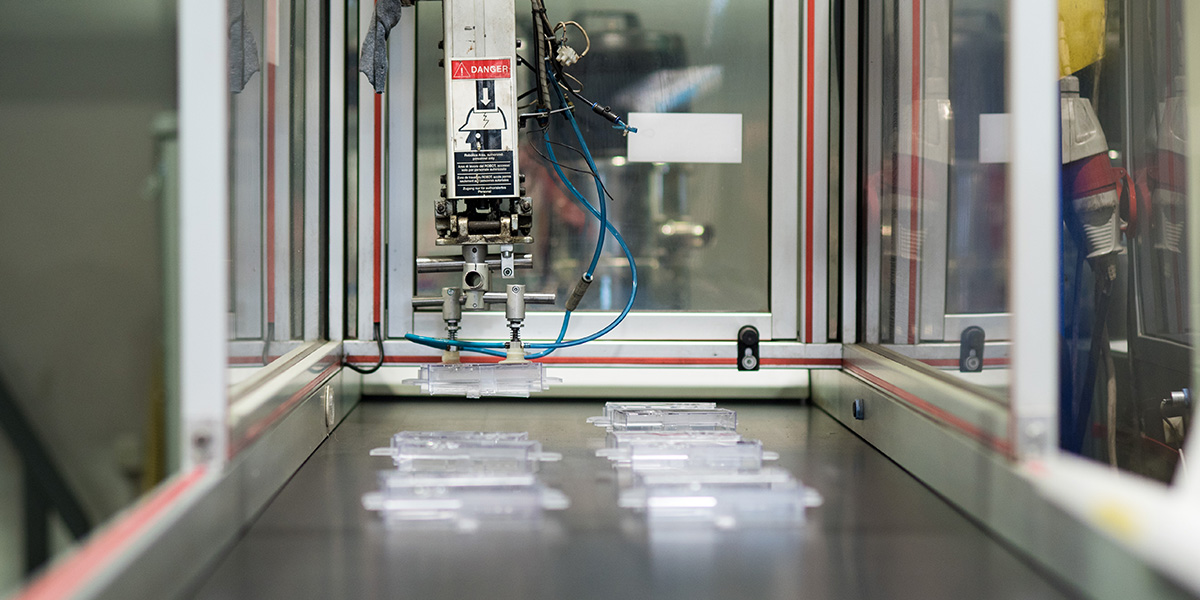

With the reduction or complete elimination of the human factor in the manufacturing process, automated production line proves to be more effective and reliable. Not only does an automated line enable faster production, but it also gives us the possibility of continuous operation, which is almost impossible where the human factor is involved. Furthermore, the quality of the product is normally more stable once the optimal solution is reached.

Automated production line allows more flexibility

Moreover, the automated production line gives the whole manufacturing process more flexibility. Since the work post no longer depends on human workers, the production line doesn’t have to be designed to meet human needs. The engineers don’t have to focus on the safety and comfort of workers when they plan an automated production line. Instead, they can pay more attention to its effectiveness, which opens a wide variety of possibilities when it comes to assembling such production mechanisms.

Once the manufacturing process is fully automated, it can be controlled remotely, which is another way of achieving higher levels of flexibility and lowering costs and/or enhancing productivity.

As you can see, the advantages of the automated production line are limitless, not just in manufacturing furniture components but also in other industries. With the aspiration for a better environment, we have high hopes that optimization of production lines in the near future will further focus not only on eliminating production costs but also its impact on our planet. Like we said in the opening, there is always room for improvement, and here at Skaza we aspire to find it.

An excellent partnership is a key to success. Fill in the form below and download our case study about milestones while building the future of energy with one of our biggest partners for more than 15 years.