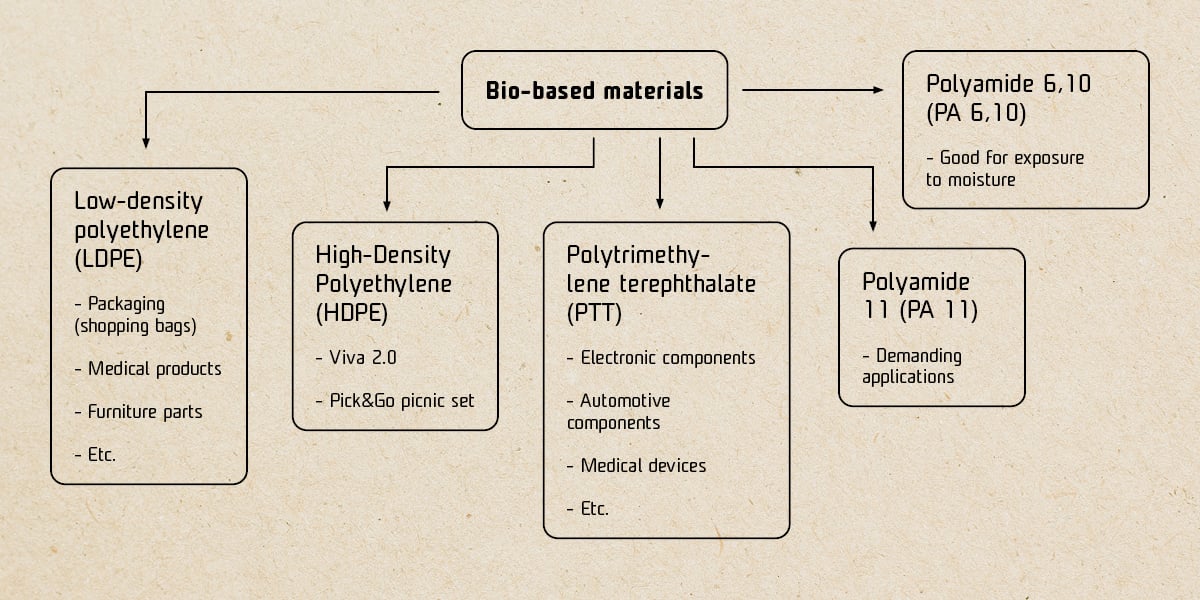

Are you developing a new plastic product and considering using sustainable bio-based materials? Maybe you have already decided to use bio-based materials but aren't sure which one to choose? To help you make this decision, we have prepared a list of the top five bio-based materials suitable for injection molding.

Download our e-book about the sustainable materials we use in our manufacturing process >>

Here at Skaza, we strongly believe in using eco-friendly materials and sustainable resources (recycled and bio-based materials) in our plastic products. We follow our vision by producing 85% of Skaza branded products from sustainable materials and aim to increase this number even more in the coming years. Our focus is on producing reusable plastic products that can be efficiently recycled, as we believe this is the right path to a sustainable future and keeps our planet green. Therefore, this article focuses on non-biodegradable bio-based materials as they are generally better suited for such products.

Low-density polyethylene

Low-density polyethylene (LDPE) is a material you've no doubt encountered, as it's a very common packaging material used for products like shopping bags. However, LDPE can also be used for injection molding of plastic products such as medical products, food containers, cosmetic and pharmaceutical packaging, furniture parts, toys, industrial parts, etc. LDPE is used in applications where a very flexible and tough material is required. In 2019, 17.4 % of all plastic products manufactured in Europe were made from LDPE and linear LDPE, making it the second most used material.

LDPE is traditionally made from fossil resources, but bio-based versions have also become commercially available in recent years. Bio-based materials are typically made from sugar cane by producing ethanol and then converting it to ethylene, which is used to polymerize LDPE. Skaza already uses bio-based LDPE to produce sustainable cutting boards from our Solo line.

High-Density Polyethylene

High-density polyethylene (HDPE) is LDPE's bigger brother. It is made from the same basic building blocks but has higher stiffness, strength, hardness, and temperature resistance but lower flexibility. Like LDPE, it is used in many different industries for applications requiring slightly stiffer and stronger materials than LDPE. HDPE is also one of the most commonly used polymers, ranking third in terms of frequency. However, if we consider only the injection molding process, it is even more widely used than LDPE.

HDPE is also one of the most extensively used bio-based materials, here at Skaza, where we use bio-based HDPE to produce injection-molded plastic products. For example, the entire Viva 2.0 dinnerware set is made from bio-based HPDE, as are most of the products in our Pick & Go picnic set.

Polytrimethylene terephthalate

If you want to make a plastic product from environmentally friendly bio-based materials, but the mechanical and thermal properties of HDPE are not sufficient for your application, then polytrimethylene terephthalate (PTT) might be the right answer. PTT has similar properties to its polyester cousin polybutylene terephthalate (PBT), but is also made from renewable resources. However, unlike bio-based LDPE and HDPE, where the majority (about 95%) of the components are made from renewable resources, PTT is only partially bio-based (37%). Nevertheless, it is an excellent choice for more demanding applications, such as electronic components, automotive components and medical devices, as well as other consumer and industrial products. The advantages of PTT are high dimensional stability and low moisture absorption. In recent years, fully bio-based alternatives to PTT, such as polyethylene furanoate (PEF), have also emerged but are not yet commercially available.

Polyamide 11

Polyamides are a well-known class of engineering polymers with excellent physical properties. Polyamide 11 (PA 11) is a fully bio-based specialty polyamide produced from castor oil. Key advantages of PA 11 are low density, low moisture absorption, high dimensional stability, excellent chemical resistance, low permeability and high impact strength. Therefore, it is used in many demanding applications, such as automotive, pneumatic, aerospace, oil and gas, medical, food packaging and sports equipment.

Polyamide 6,10

Polyamide 6,10 is another popular item on the list of bio-based materials with excellent physical properties. Compared to PA 11, it offers higher strength and temperature resistance, but is only partially bio-based (bio-based content of about 60%). PA 6,10 has similar mechanical and thermal properties to fossil-based PA 6, but has lower moisture absorption, making it more suitable for applications where plastic parts are exposed to moisture. Since PA 6,10 is partially bio-based, it is also a more sustainable alternative to PA6.

Still not sure which bio-based materials are best for your product? Contact us and we will be happy to help you find the best solution for your product.

Find out more about how we incorporate sustainable materials into our production process. Fill in the form and download the e-book with educational content.